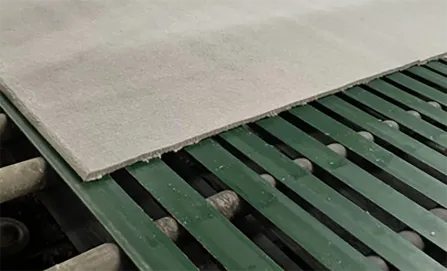

fibre false ceiling materials

In residential settings, a 12x12 ceiling access panel can be utilized in laundry rooms, kitchens, or areas where ductwork is present. It provides homeowners with a convenient way to access these systems without needing extensive renovations or invasive procedures. Such access is essential not only for routine maintenance but also for troubleshooting potential issues that may arise over time.

...